A Practical Guide to Custom Cake Packaging for Growing Bakery Brands**

Thank you for reading this post, don't forget to subscribe!Introduction: Why Cake Boxes Matter More Than Ever

In today’s competitive bakery market, a cake box is no longer just a container. It is a silent salesperson, a brand ambassador, and often the very first physical touchpoint between your product and your customer.

As a packaging manufacturer working closely with bakeries, dessert brands, distributors, and private-label companies, we’ve seen one thing very clearly: the right cake box can directly influence product value, customer perception, and repeat orders.

From boutique cake shops to large-scale bakery chains, from OEM orders to ODM customized solutions, cake boxes play a crucial role in protecting delicate products, supporting logistics, and communicating brand identity. This article shares practical insights from real production experience—what makes a good cake box, how to choose the right materials and structures, and how custom packaging helps bakery businesses scale sustainably.

What Is a Cake Box? (And Why Definition Matters in B2B)A cake box is a specially designed packaging solution used to store, protect, transport, and present cakes and baked desserts. But in B2B terms, a cake box is not just a “box”—it is a system.

It involves:

- Structural engineering (load-bearing, stacking, stability)

- Material selection (food safety, rigidity, sustainability)

- Printing and branding (visual impact, consistency)

- Manufacturing scalability (OEM / ODM efficiency)

- Logistics compatibility (shipping, storage, export standards)

For wholesale buyers, distributors, and brand owners, understanding this broader definition helps avoid costly mistakes later in production.

Common Types of Cake Boxes in the Market

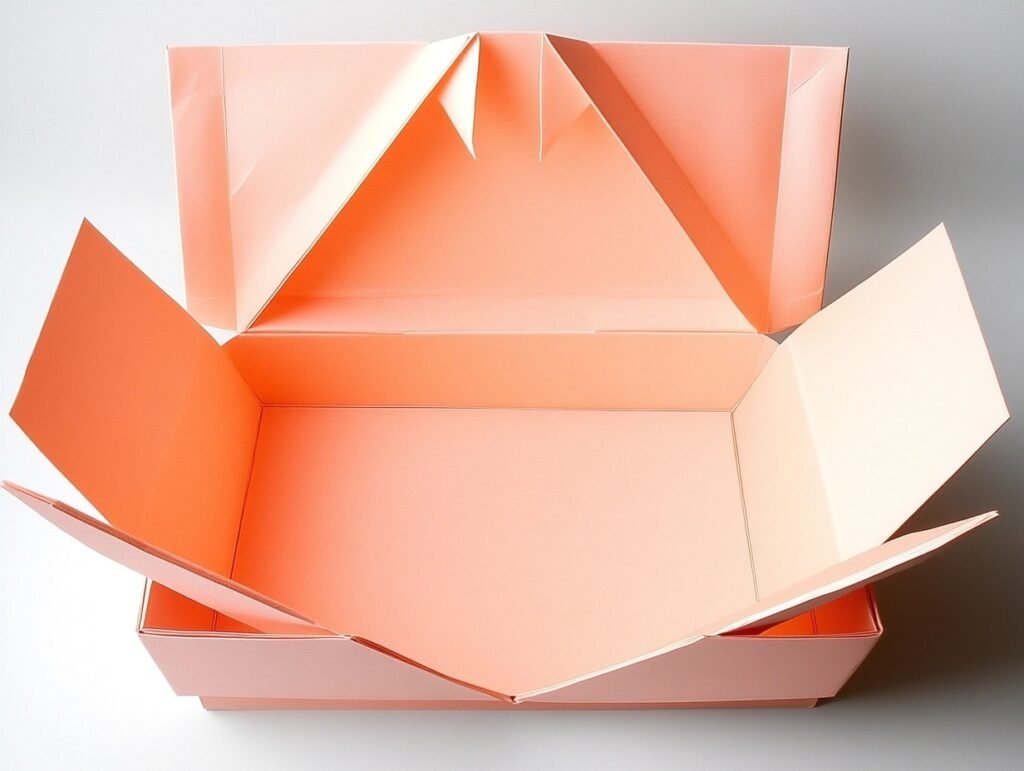

1. Folding Cake Boxes (Flat-Pack)

Folding cake boxes are the most common choice for bakeries and distributors. They are shipped flat, saving storage and transportation costs, and assembled quickly at the point of use.

Advantages:

- Cost-effective for bulk orders

- Easy to store and transport

- Suitable for OEM mass production

Best for:

Daily bakery operations, supermarket suppliers, franchise chains.

2. Rigid Cake Boxes (Premium & Gift Cakes)

Rigid cake boxes are often used for high-end cakes, wedding cakes, or seasonal gift products. They offer stronger protection and a premium unboxing experience.

Advantages:

- High perceived value

- Excellent structure and protection

- Ideal for branding and gifting

Best for:

Luxury bakeries, holiday collections, custom brand projects.

3. Window Cake Boxes

Window cake boxes feature a transparent PET or PVC window that allows customers to see the product inside without opening the box.

Advantages:

- Enhances visual appeal

- Increases impulse purchases

- Builds trust through product visibility

Best for:

Retail shelves, display counters, takeaway cakes.

4. Handle Cake Boxes

Designed for convenience, handle cake boxes make carrying safer and more comfortable—especially for larger or heavier cakes.

Advantages:

- Improved user experience

- Reduced risk during transport

- Strong functional value

Best for:

Takeaway services, celebration cakes, long-distance transport.

Materials Used in Cake Box Manufacturing

Choosing the right material is a balance between cost, performance, sustainability, and brand positioning.

Food-Grade Paperboard

Most cake boxes are made from food-grade paperboard, ensuring safety and compliance with international standards.

Common options include:

- SBS (Solid Bleached Sulfate)

- Kraft paperboard

- CCNB (Coated Clay News Back)

Each material offers different strengths in rigidity, printability, and environmental impact.

Sustainable & Eco-Friendly Materials

Sustainability is no longer a trend—it’s a requirement. Many B2B buyers now request:

- FSC-certified paper

- Recyclable or biodegradable materials

- Plastic-free window alternatives

Eco-friendly cake boxes not only reduce environmental impact but also help brands align with modern consumer values.

Custom Cake Boxes: OEM & ODM Solutions Explained

OEM Cake Boxes

OEM (Original Equipment Manufacturer) cake boxes are produced based on the buyer’s existing design and specifications.

OEM is ideal if you already have:

- Finalized box structure

- Artwork and branding files

- Clear material requirements

It offers efficiency, consistency, and cost control for repeat orders.

ODM Cake Boxes

ODM (Original Design Manufacturer) cake boxes involve collaborative development. The manufacturer supports:

- Structural design

- Material optimization

- Visual branding suggestions

- Cost-performance balancing

ODM is ideal for:

- New bakery brands

- Businesses entering new markets

- Companies seeking differentiation without in-house packaging teams

How Custom Cake Boxes Add Real Business Value

From our experience working with global clients, custom cake boxes deliver value in several measurable ways:

- Reduced product damage during transport

- Improved shelf presence and brand recognition

- Higher perceived product value

- Better customer experience and repeat purchases

- Optimized logistics and storage efficiency

Packaging is not an expense—it is an investment in brand growth.

Key Considerations When Ordering Cake Boxes in Bulk

Before placing a wholesale cake box order, consider the following:

- Cake size and weight (internal dimensions matter)

- Transportation method (local delivery vs export)

- Storage conditions (humidity, stacking)

- Brand positioning (budget vs premium)

- Regulatory requirements (food safety standards)

Clear communication with your packaging supplier saves time, cost, and revisions.

The Role of Printing in Cake Box Branding

Printing transforms a simple box into a brand experience.

Common printing techniques include:

- Offset printing

- Flexographic printing

- Hot foil stamping

- Embossing and debossing

- Spot UV coating

Well-executed printing reinforces brand identity and communicates professionalism instantly.

Working with a Reliable Cake Box Manufacturer

A reliable packaging partner offers more than production capacity. They provide:

- Consistent quality control

- Stable lead times

- Export experience

- OEM & ODM flexibility

- Long-term cost optimization

In B2B packaging, trust and reliability are just as important as price.

Conclusion: Cake Boxes as a Strategic Packaging Choice

Cake boxes may seem simple, but behind every well-designed box is thoughtful engineering, careful material selection, and strategic branding.

For bakeries, distributors, and brand owners, choosing the right cake box supplier is not just about packaging—it’s about building a scalable, sustainable, and recognizable brand.

If you are looking to develop or upgrade your cake packaging—whether through OEM efficiency or ODM innovation—investing in the right cake box solution can make a measurable difference in your business growth.